When it comes to industrial environments, reliability and performance are extremely important. Machinery is no exception to the rule – take industrial PCs for example. You may be in the market for an industrial PC – or know it’s something you need – but with so many options on the market, how do you know which one to choose?

When it comes to industrial environments, reliability and performance are extremely important. Machinery is no exception to the rule – take industrial PCs for example. You may be in the market for an industrial PC – or know it’s something you need – but with so many options on the market, how do you know which one to choose?

First, What Exactly is an Industrial PC?

If you are new to this type of machine – an industrial PC has quite a lot in common with a personal computer (PC). These types of computers are typically found in homes, workplaces. You might even be reading this guide on one right now!

However, the key difference in an industrial PC is that it is specifically designed to work reliably and efficiently in industrial environments. As you can probably guess, a typical PC wouldn’t fare very well on a factory floor. There’s high temperatures, dust, debris, and all sorts of environmental factors that could cause breakdowns, low availability, and performance issues. And with modern-day industrial systems that rely on computers, a regular PC just isn’t up to the job.

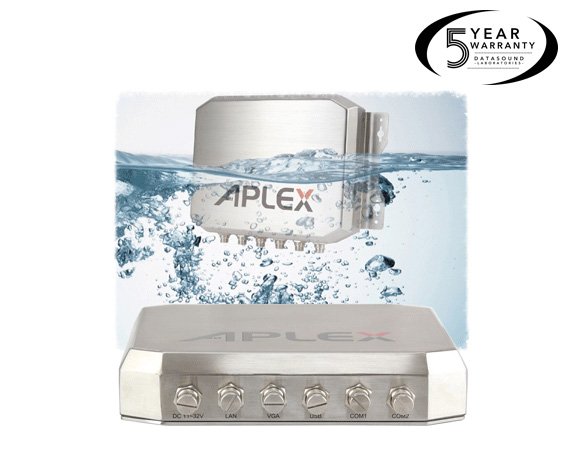

One of the first things you’ll notice with an industrial PC is what they’re made from. These are typically strong and resilient materials that can survive challenging environments. Think metals aluminium and/or steel. This is particularly important for an industrial PC’s outer enclosure, as this will bear the brunt of the majority of an industrial environment’s conditions.

Another benefit of these types of materials is how they enable Industrial PCs to function in a wide temperature range. They can withstand both high and low temperatures, ensuring consistent operation even in extreme environmental conditions. This is especially important in industry workspaces like manufacturing plants, where things can get really heated.

Along with the heat is the dust, debris, and moisture in an industrial setting. You’ll notice on a lot of industrial PCs that they have something called an IP rating. This stands for Ingress Protection. This is an indicator of how resistant that is to water and dust – all things that could easily damage a computer. These conditions can be further exaggerated by the vibrations and shocks that machinery and equipment give off. Industrial PCs are designed to withstand all of this, making sure systems operate without interruptions and – probably most importantly – don’t fail. In short, Industrial PCs are pretty important to industry operations!

How to Choose an Industrial PC

So we’ve covered what exactly an Industrial PC is, but when you’re in the market for one, how do you know which one to choose? There’s several points to consider that point to whether a particular model is suited to your industrial space. Remember, it will need to withstand your particular environment, and if it will need to deliver on business requirements. Will it deliver the operations your operations need? Are there other models that are better suited for the job?

Here’s a few things to keep in mind whilst you’re looking for your new industrial PC.

Look For Robust and Durable Construction

As mentioned earlier, industrial settings can be intense – equipment and machines can be exposed to extremes in temperature, humidity, dust, debris, vibration, and electrical noise. To ensure industrial PCs operate reliably in these conditions – and importantly don’t corrode – they should have a sturdy construction with high-quality components. Some models also come with fanless and cableless designs to further prolong their life cycles. In the long term, this is going to save you money. Longer lasting Industrial PCs definitely affect the bottom line.

Assess Temperature and Environmental Specifications

Double check that the temperature range of an industrial PC is suited to the space you want it to operate in. We recommend looking for models with wide temperature ranges to accommodate extreme hot and cold. Remember to also check the IP (Ingress Protection) ratings too. As we mentioned above, these indicate the level of protection against debrid and water. If you’ve got a particularly moist or dusty workspace, you want something that’ll handle these conditions.

Are There Suitable Expansion and Connectivity Options?

Keep in mind what your existing industrial applications need to connect to other systems, as well as potential expansion plans. For example – if you need to allow additional cards or modules for specialised functionality, you’ll need industrial PCs with numerous expansion slots. You’ll want to ensure that the model you’re interested in has USB, Ethernet, serial ports, and/or wireless communication options. Otherwise, it’ll become tricky to integrate it with your existing hardware and computer systems.

Is the Processing Power and Performance Suitable?

Examine the Industrial PC’s processing power and performance capabilities. Is this in line for what your systems need? To ensure there’s adequate processing power for your particular job, take into account variables such the CPU type, clock speed, number of cores, and accessible memory (RAM).

Is the Operating System Compatible?

This is an important one! You’ll want to ensure that the Industrial PC is compatible with the operating system you use – or want to use – for your applications. Check for support and drivers for your preferred operating system, whether it’s a Windows-based, Linux, or another specialised industrial operating system.

You’ll also want to ensure that the industrial PC you choose provides the processing power, RAM requirements, and storage your application(s) need(s). You’ll want it to handle your workloads, even improve on how effectively they process them.